In the realm of modern construction, ensuring a stable and durable foundation is crucial for the longevity of any structure. One innovative solution gaining traction among engineers and builders is the use of helical piles. These helical piles offer numerous advantages, including enhanced load-bearing capacity, quick installation, and minimal disruption to the surrounding environment. This step-by-step guide aims to demystify the installation process of helical piles, equipping contractors and DIY enthusiasts with the knowledge necessary to achieve stronger foundations.

Helical piles, also known as screw piles, are advanced foundation systems that are designed to be driven or screwed into the ground. Their spiral design allows them to penetrate various soil types more effectively than traditional foundation methods. As more projects require sustainable and cost-effective solutions, understanding the proper techniques for installing helical piles becomes increasingly important. In this guide, we will explore the essential steps for installing these structures, addressing critical considerations that can impact the integrity and performance of a foundation. By mastering the installation process, builders can ensure that their projects stand the test of time, featuring a robust foundation that contributes to overall safety and durability.

Helical piles, also known as screw piles, are an innovative foundation support system designed to provide strength and stability to structures. These piles consist of long steel shafts with helical blades attached, which are drilled deep into the ground to reach stable soil or bedrock. One of the primary benefits of using helical piles is their ability to distribute weight evenly across a larger area, which reduces the risk of settling or shifting over time. This characteristic makes them ideal for various applications, including residential buildings, commercial foundations, and even towers.

In addition to their structural benefits, helical piles offer significant advantages during the installation process. The installation method is less invasive compared to traditional piling techniques, resulting in minimal disruption to the surrounding environment. Moreover, they can be installed in most weather conditions and can be used in areas with limited access. Their versatility also allows for easy removal and reinstallation, making them an excellent choice for projects requiring temporary foundations. With their growing popularity in construction, understanding the benefits of helical piles is crucial for anyone looking to enhance foundation strength effectively.

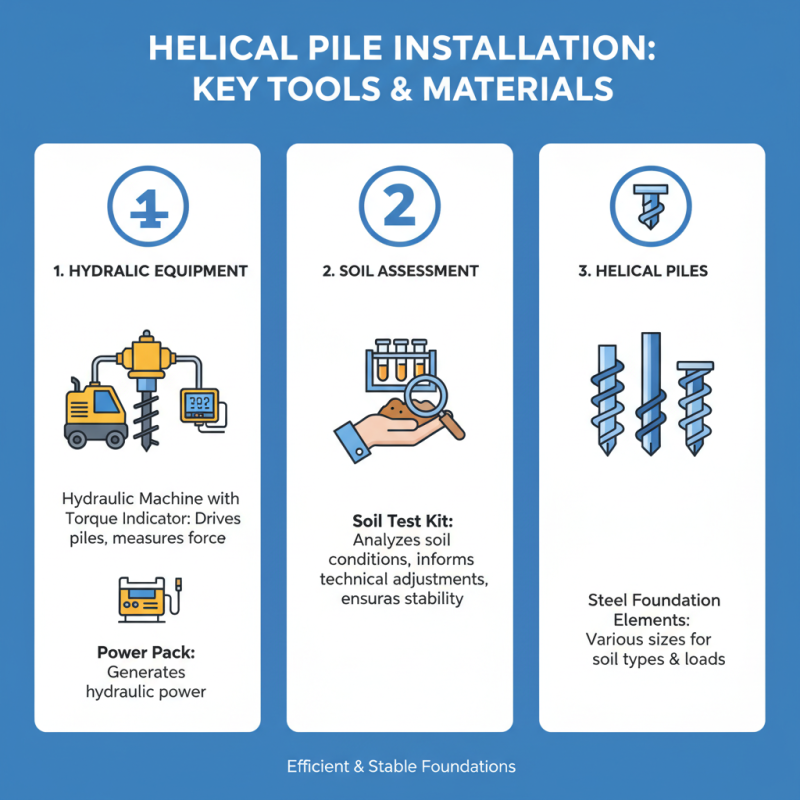

Installing helical piles requires specific tools and materials to ensure a successful and efficient process. First and foremost, a hydraulic machine equipped with a torque indicator is essential. This machinery assists in driving the helical piles into the soil, providing the necessary force to penetrate deeper layers. Additionally, a power pack may be needed to generate hydraulic power for the equipment. A soil test kit will also be valuable for assessing the soil conditions before installation, allowing for adjustments in technique and ensuring stability once the piles are in place.

In terms of materials, the helical piles themselves are critical—they are typically made of steel and designed to withstand high loads. Couplings, which connect the sections of piles, must also be included when planning the installation. Accessories such as a level, a measuring tape, and safety gear like hard hats and gloves are indispensable to maintain site safety and accuracy during the process. Having a well-organized setup of these tools and materials streamlines the installation procedure, contributing to the overall effectiveness of creating stronger foundations.

Before installing helical piles, proper site preparation is crucial to ensure a strong and stable foundation. Begin by assessing the soil conditions on your site. Conduct a thorough soil test to determine its bearing capacity and composition. This information will guide your decisions on the type of helical piles required and their appropriate depth and spacing. Additionally, check for underground utilities or obstructions that might affect the installation process.

Once the soil assessment is complete, clear the site of any debris, vegetation, or large rocks. This step is vital as it allows for a safe installation area and prevents any potential damage or interference during the helical pile installation. Create a level surface to ensure that the piles can be installed vertically, which is critical for load distribution.

Tips: Use caution when operating heavy machinery during site preparation to prevent accidents. If your site has significant slope or drainage issues, consider consulting with a civil engineer to design an appropriate grading plan. Also, mark the locations of the helical piles ahead of time to streamline the installation process and minimize rework. This proactive approach will help secure a solid foundation and enhance the longevity of the structure being built.

When installing helical piles, adhering to proper guidelines is essential to ensure a sturdy and reliable foundation. According to a report by the Deep Foundations Institute, installing helical piles correctly can enhance the load-bearing capacity of structures by more than 50%, making them a preferred choice for various applications.

To begin, it is crucial to assess the soil conditions and determine the required pile type and size based on the anticipated loads. Soil testing should include shear strength analysis, as it can impact the installation method and pile performance.

Once the appropriate specifications are determined, the installation process must be executed with precision. It involves using a hydraulic torque motor to screw the piles into the ground, ensuring that they reach the designed depth while maintaining vertical alignment. The American Society of Civil Engineers recommends continuous monitoring during the installation phase to verify the torque and depth, which are critical indicators of the pile's load capacity.

Neglecting these guidelines can lead to compromised structural integrity and increased construction costs, underscoring the importance of meticulous planning and execution in helical pile installation.

The post-installation inspection and maintenance of helical piles are crucial in ensuring the long-term performance and stability of foundations. According to the International Association of Foundation Drilling (ADSC), helical piles can support loads exceeding 200 kips when installed correctly. However, regular inspections are essential to identify any signs of distress or structural issues that may arise over time due to soil shifts or environmental changes. These inspections should focus on analyzing the load distribution, vertical deflection, and any visible signs of corrosion, particularly in areas exposed to moisture.

In a recent report by the Foundation Engineering Research Institute (FERI), it was highlighted that routine maintenance can extend the lifespan of helical piles significantly, with data suggesting that proper upkeep can increase their service life by up to 30%. This involves not only visual inspections but also the implementation of load monitoring systems that track the performance of the piles over time. By proactively addressing any wear and tear, foundation engineers can mitigate potential issues before they escalate, maintaining the integrity of the structure and protecting investment values.